Benefits of electric motor repair

Single-phase motors are generally used in the domestic sector because they require less power. A company needs to choose its type of motor well under the desired objective to avoid certain breakdowns.

Industrial and agricultural companies must, to maximize the return on investment of their electric motors and their industrial installations, protect themselves against certain electrical and mechanical problems and set up a maintenance plan. Theelectric motors repair shop is very helpful for domestic purposes.

1. Engine guards

Despite their ease of use and reliability, electric motors are subject to several problems. It is therefore important that they are protected against the following risks:

Moisture-related damage: Motors are extremely sensitive to moisture, which can cause electrical failures or corrosion of bearings. Therefore, it is imperative to protect them from humidity by placing them in a dry environment, by placing protective covers, or by protecting them when cleaning the installations with water. On the other hand, lubricating the bearings when possible minimizes the effect of humidity and prolongs their life.

Motor overload: An overload problem occurs when the motor receives an amount of current greater than its safety limit. Protecting the motor against overloads, therefore, consists of automatically disconnecting it from the power supply when the temperature of the windings reaches a high level, thus preventing them from catching fire. This protection is normally in place when the motor is installed and should not be disabled.

Loss of field excitation: This risk appears when the motor reaches high speed (more than 20% above normal). This risk is more frequent for DC or winding motors and must be avoided by respecting the maximum rotational speed of the motor.

A motor can also face other problems such as voltage drop, overheating, etc. Therefore, it is recommended to protect against these failures if the risk is high. The most important thing is to ensure that the motor is protected by a motor circuit breaker, a variable speed drive, or a starter, depending on its use.

On the other hand, it is also essential to establish a maintenance plan to avoid certain damages which can cause total or partial deterioration of the engine.

2. An effective maintenance strategy for electric motors

Just like other industrial equipment, electric motors need regular servicing and maintenance. Engine maintenance begins in the first place with its installation. Improper installation can, for example, result in the misalignment of the shaft to the load. This defect causes premature wear of mechanical components, such as bearings. Electricmotor repair services help you in water-related problems.

During installation, it is also necessary to check the programming of the distribution circuit breakers and adjust them if necessary to avoid untimely and unnecessary stops of the motor during use.

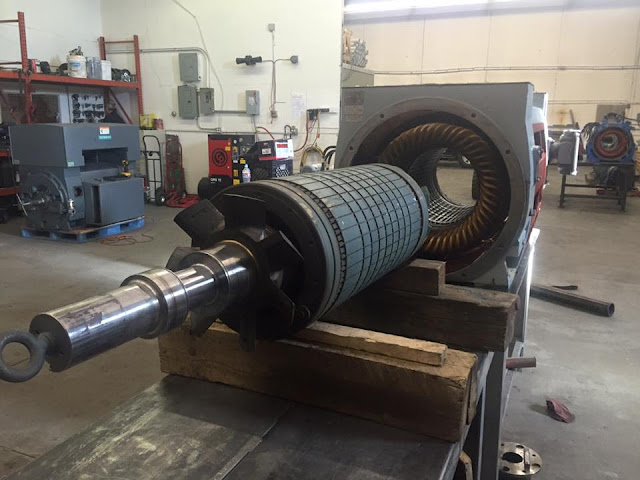

This regular maintenance, which constitutes preventive maintenance of the engine, must be accompanied by corrective maintenance if necessary. It intervenes when a problem is detected and is generally done by a specialized and qualified technician to carry out tasks such as changing the bearings or rewinding the motor.

For an effective maintenance strategy, industrial and agricultural companies should keep a register in which the checks and interventions carried out on the engine are recorded and their date. In this way, the technicians working on the installation will be better informed of the condition of the motor and its history.

The proper functioning of an industrial or agricultural installation is largely guaranteed by its motor. Therefore, it is imperative to maintain it well to save energy and ensure better performance, longer service life, and fewer breakdowns. Electric motor repair near me provides there best of their services in your locality.

.jpg)

Comments

Post a Comment